Tutorial 2 - Advanced Sequence (Exercise 2)

Exercise Information

A factory processes boxes with 20 pieces each, of four different types, using two lines of production. The first line consists of processing types 1 and 2 and it is composed by two machines. One unpacks and and processes, and the other processes and packs. The second line consists of another set of two machines, one unpacks and processes types 3 and 4, and the other processes and packs them. Finally the two lines meet at the end on a double packing machine (Machine5B). This machine unites items type 1 with 3 and types 2 with 4.

On this factory, sets of items of different types (1 and 2 vs 3 and 4) are only queued together on the initial buffer, soon to be split into different processing lines, only to be mixed again on the final Buffer as an united set. There are also intermediate buffers before the double pack machine (Machine5B).

This scenario includes an inspection Bench, where items are inspected for 50 seconds after the end of the packing process of boxes, and inspected again after the final assembly. Build the model that simulates this description.

The cycle time of each machine is 10 times the number of its type of item being processed. That is, to process items of number 1, it takes 10 seconds, number 2 - 20 seconds, and so on. It will be necessary to use the "Values by case" from the cycle time picklist, to ensure different processing times for each type.

The last machine, has a cycle time of 100s, and a setup time sensitive to change of type, of 100 seconds between types 1 to 2 and 3 to 4, and 200 seconds between types 1 to 3 and 2 to 4, and vice-versa. The load and unload time of all machines is 10 seconds long.

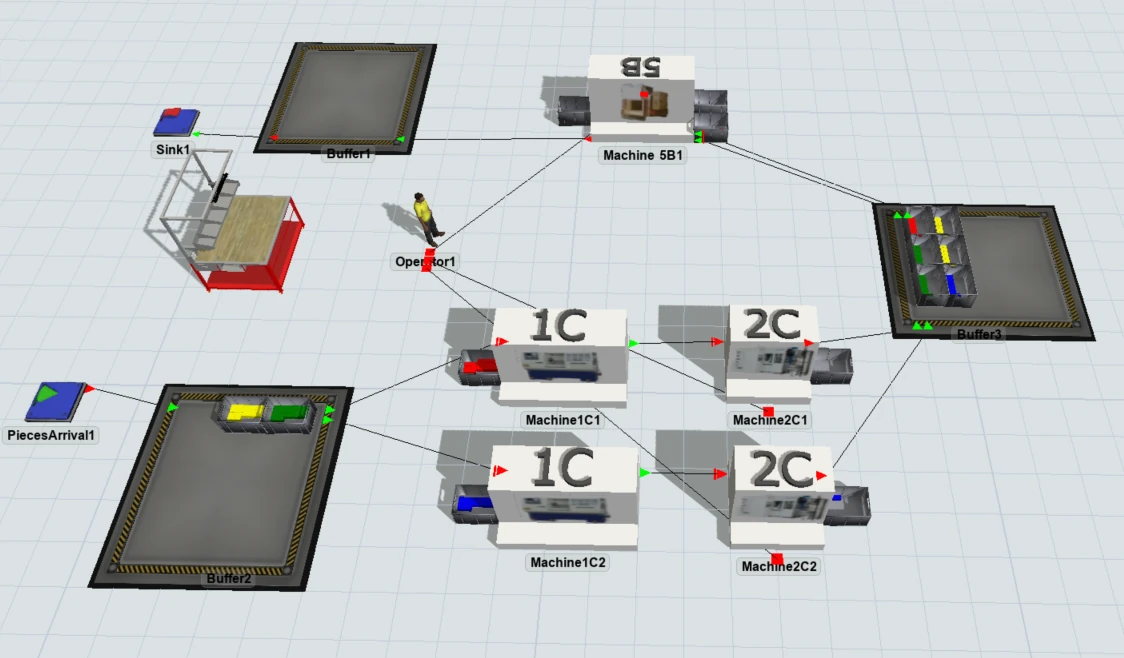

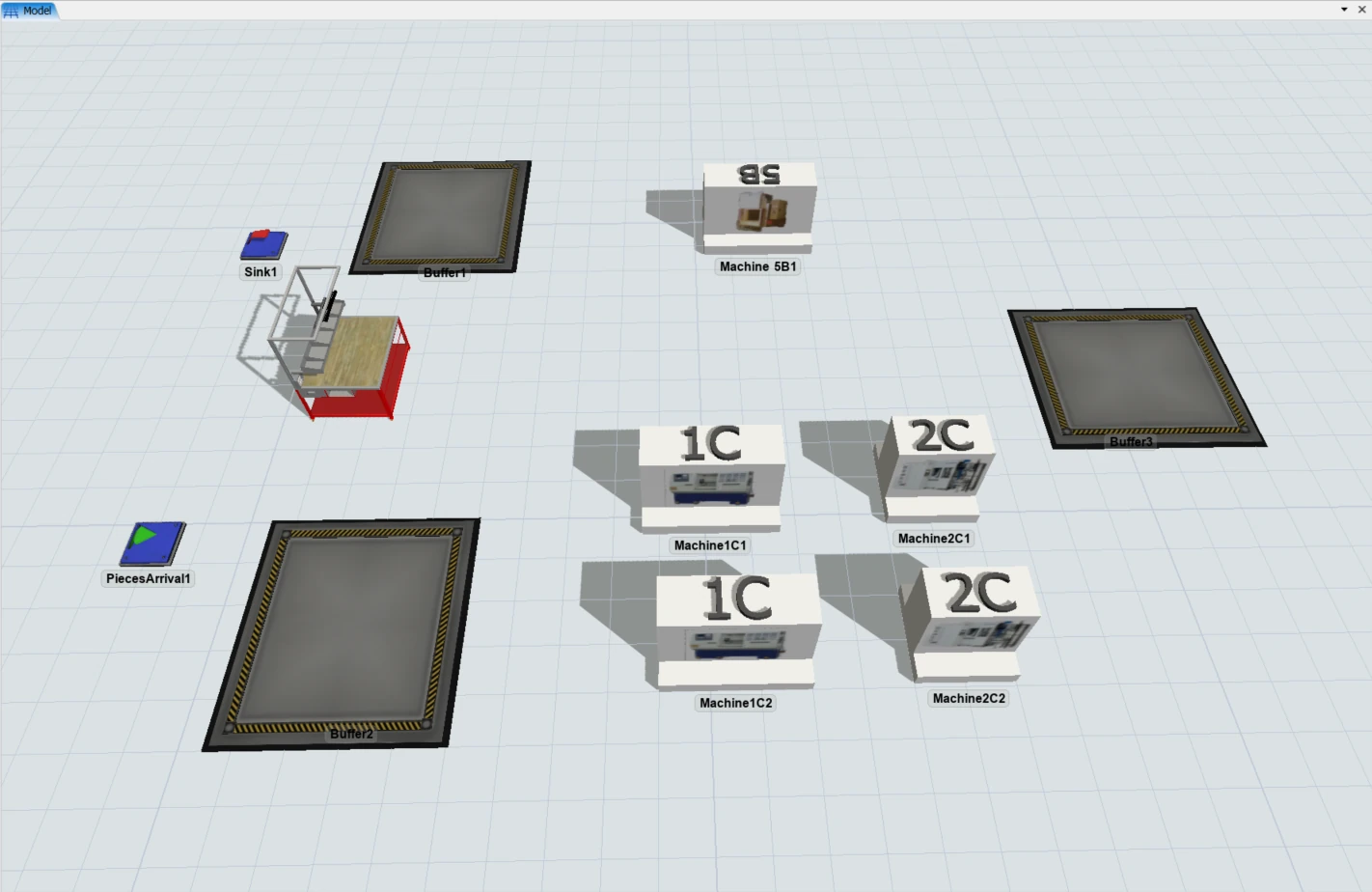

Object Creation

To build the solution, we shall first create the described objects and the other essential objects for the correct production flow:

- - Create the Pieces Arrival, the Sink, the entry/exit Buffers and the Bench.

- - Create five machines, four of them will be packing Machines at the start of the 2 lines, after Buffer1 and Before the Buffer2. Then, create the assembly machine (DoublePack - Machine5B) between Buffer2 and 3.

- - Create another flow (using the A key): Pieces Arrival -> Buffer 1 -> Machine 1 and Machine 2 -> Machines 3 and 4 -> Buffer 2 -> Machine5 -> Buffer 3 -> Sink.

Your model should look like the following:

Machine Configuration

We'll use the "Properties Panel" on the right corner to configure the objects, according to the problem description.

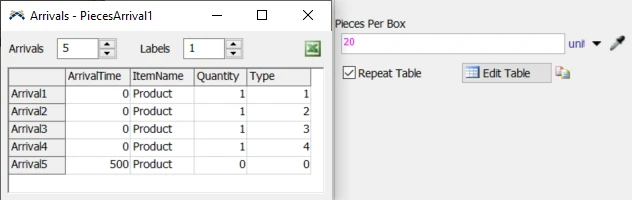

- First, set the number of pieces per box to 20 units. Edit the arrivals table to contain 5 rows. Set the information like the following:

- Next, configure the machines following the guide below:

Machine 1C1:

Type: 1 e 2

Load/Unload: 10s + 10s

Cycle time: 1-> 10s, 2-> 20s

Setup: 0s

Mode: Doesn't pack on the Exit

UseInspectionBench: No

Machine 2C1:

Type: 1 e 2

Load/Unload: 10s + 10s

Cycle time: 1-> 10s, 2-> 20s

Setup: 0s

Mode: packs on the Exit

PiecesPerBox: 20

UseInspectionBench: Yes 50s

Machine 1C2:

Type: 3 e 4

Load/Unload: 10s + 10s

Cycle time: 3-> 30s, 4-> 40s

Setup: 0s

Mode: Doesn't packs on the Exit

UseInspectionBench: No

Machine 2C2:

Type: 3 e 4

Load/Unload: 10s + 10s

Cycle time: 3-> 30s, 4-> 40s

Setup: 0s

Mode: packs on the Exit

PiecesPerBox: 20

UseInspectionBench: Yes 50s

Machine 5B:

Type: All

Load/Unload: 10s + 10s

Cycle time: 100s

Setup: 1->2 100s, 3->4 100s, 1->3 200s, 3->4 200s.

Mode: packs on the Exit

PiecesPerBox: 20

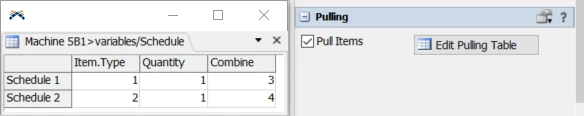

Pulling: Type 1 with 3, e 2 with 4.

UseInspectionBench: Yes 50s

- To configure the inspection site, with the dropper under the bench reference section select the Bench. Add an operator and connect them (Using the S key).

- To configure the stock, edit the Buffer to create 20 pieces per box, add a table to the entry stock with 2 boxes for each type. You should get the following configuration:

- Lastly, configure the correct flow for each type. Use the output of "Ports by Case" for the buffers preceeding the machines. Boxes types 1 and 2 should be directed to port 1, boxes type 3 and 4 should be directed to port 2. This configuration should only be set for the initial Buffers.

- It will be necessary to configure the pulling behavior for Machine5B, to assemble the corresponding items. This configuration should look like the following:

With these settings applied, your model is ready. Run the simulation for 8 hours, or 28.800s to obtain a production of 41 boxes.