Tutorial 1 - Simple Sequence Guide (Exercise 1)

Exercise Information

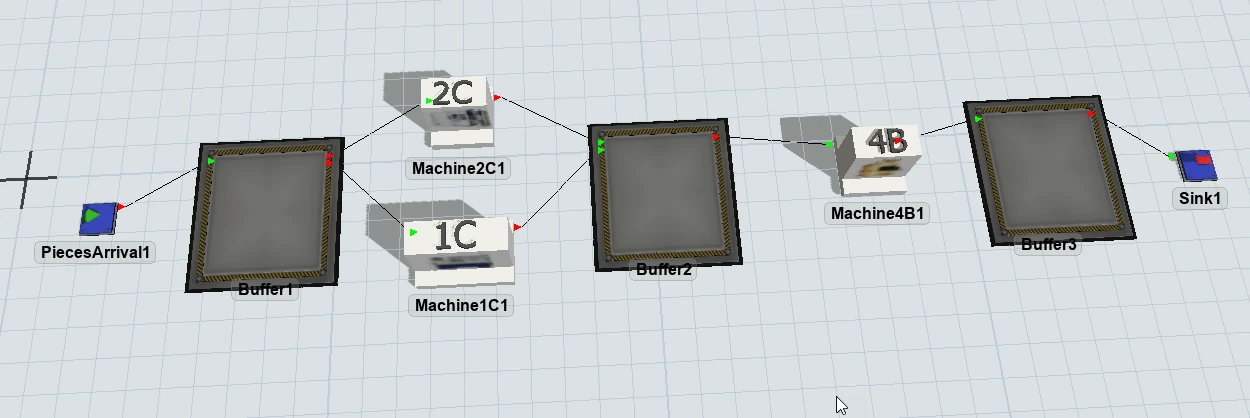

A factory processes boxes of 20 pieces each, of two different types, using firstly, two packing machines, then a simple machine (Machine 4B). Type 1 and 2 take 10 and 20 seconds respectively to finish being processed. All machines have a load and unload time of 10 seconds. There are lines before and after the packing and simple machines. Create a model corresponding to this description of the factory.

Object Creation

To build the solution, we shall first create the described objects and the other essential objects for the correct production flow:

- - Drag into the model the Pieces Arrival, the Sink and the entry/exit Buffers.

- - Create three machines, two Packing Machines at the beggining, after Buffer1, and a simple Machine4B between Buffers 2 and 3.

- - Connect the following flow (Using the A key) : Pieces Arrival -> Buffer1 -> Machines1 and 2 -> Buffer2 -> Machine3 -> Buffer3 -> Sink.

Your model should look like the following:

Machine Configuration

We'll use the "Properties Panel" on the right corner to configure the objects, according to the problem description.

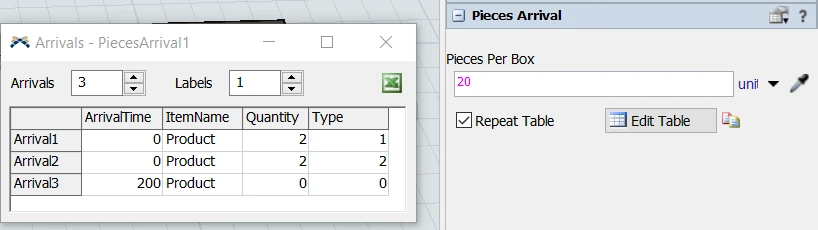

- First, set the number of pieces per box to 20 units. Edit the arrivals table to contain three rows. The first arrival consists of type 1 objects, the second, type 2. The third arrival should represent a time jump of some seconds, with quantity and type set to 0.

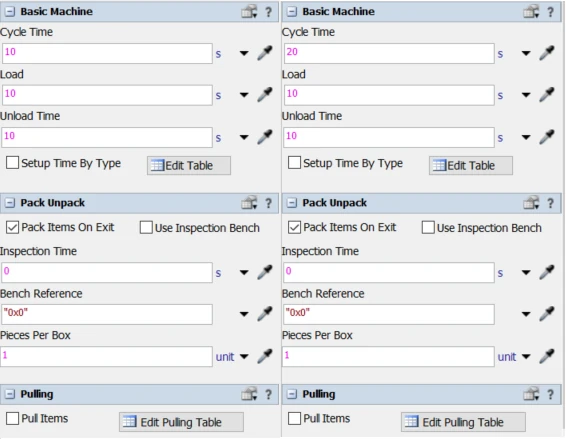

- Next, set the packing machines to pack, and each of them to process type 1 or 2. The simple machine (Machine4B) processes both types. To guarantee the right types to arrive at their respective pack machines, configure the output of Buffer1 to send to "Port By Case", and send types 1 to port 1 and types 2 to port 2. Your settings should look like the following:

- Lastly, configure the Machine4B to load and unload for 10 seconds, and have a cycle time of 15 seconds (Simple mean between processes of type 1 and 2).

With these configurations applied, your model should be ready. Run the simulation for 8 hours, or 28.800s, and obtain the production of 82 boxes.